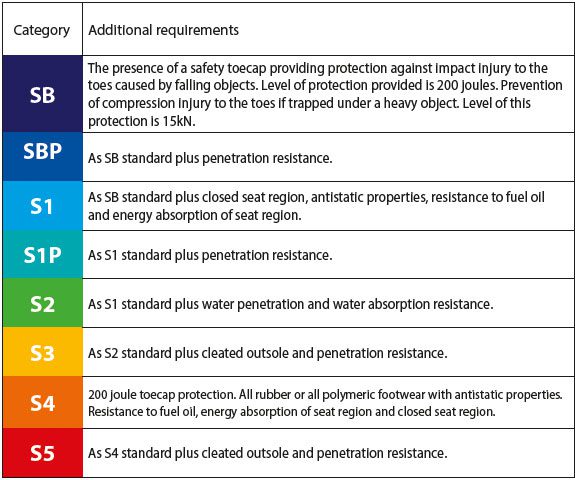

If you’re a safety professional, you know that S1, S2, and S3 safety shoes are the most important part of a good safety footwear program. But how do you know which level of protection your safety shoes should be?

Essentially the difference between a S1,S2 and S3 safety shoe are the degrees of protection the boots provide to the wearer. Please check out this guide to learn more about which safety boot is right for you.

One professional safety shoes company that produce different type of safety shoes and work boots in China.

Table of Contents

What does safety shoes standard EN ISO 20345 mean?

EN ISO 20345 is a European standard for safety shoes. It defines the minimum requirements for the personal protective equipment (PPE) that is used in workplaces and other environments where there is a risk of foot injuries.

The standard covers both general-purpose and specialist footwear, as well as non-slip rubber soles, insoles and other components.

Currently, there are two supplementary standards within it: EN ISO 20345:2011 and EN ISO 20345:2012.

EN ISO 20345:2011 is the first supplementary standard for safety footwear, which was published in 2011, and EN ISO 20345:2012 is the second supplementary standard, which was published in 2012.

Both standards are derived from EN ISO 20345:2010, Safety footwear — Protective footwear for plant personnel — General requirements and test methods. The European Committee for Standardization (CEN) has developed this standard to provide additional information about how to specify, test and verify protective footwear.

The purpose of EN ISO 20345:2011 is to provide a common language between different stakeholders involved in specifying, testing and verifying protective footwear. It provides guidance on how to specify the performance requirements of safety footwear against hazards such as mechanical hazards, electrical hazards and heat sources.

What is the S1 safety shoes meaning?

S1 safety shoes are the most common and popular type of safety footwear. They offer a high level of protection against electrical hazards, falling objects and many other types of hazards.

The S1 safety shoes are divided into two levels. The S1P safety shoes have additional protection against oil and slip resistance, while the S2 safety shoes are more suitable for work in wet conditions.

S1 safety boots are made of strong leather or synthetic materials and are equipped with a steel toe cap. The sole of the shoe is made of a composite material that prevents soles from wearing down easily. The special design features ensure that you can feel at home in your S1 safety footwear even after a long day at work.

What is the S2 safety shoes meaning?

S2 is a safety boots rating standard created by the European Standardisation Committee (CEN) in 2001.

The S2 safety shoes is defined as follows:

S2 safety footwear provides protection against low energy, shock hazards, and is designed to prevent foot injuries such as lacerations and abrasions. The protective function of these shoes is not limited to the foot but extends to the ankle and lower leg.

The S2 standard requires footwear to provide protection against lacerations due to falling objects and related abrasion by sharp edges, which could occur during handling of materials or tools with sharp edges, e.g., knives or sheets of glass or metal. It also requires protection against impact from falling objects greater than 0.5 joules.

The S2-rating does not cover electrical hazards such as electric shock or electrocution; however, additional protection may be provided by insulating soles if necessary.

What is the S1P safety shoes meaning?

S1P safety shoes is a kind of safety shoes, which is used to protect workers from injuries caused by falling and slipping.

S1P safety shoes are designed according to the standard of Europe, America and Japan, with high quality and low price.

The S1P safety shoes can be divided into two categories: one is the steel toe cap; another is the steel plate, which is often used in heavy manufacturing industries.

The most important feature of S1P safety shoes is that it has a good protection effect for foot, ankle and toes. It can effectively prevent injuries caused by falling or slipping during work process.

What is the S3 safety shoes meaning?

S3 is a safety shoe standard. It is a standard used to describe the level of protection provided by footwear against electrical hazards. The S3 standard was published by the European Committee for Standardization (CEN) in 2012 and replaces the EN ISO 20345 standard.

S3 safety shoes are designed to protect against low voltage, alternating current (AC) electrical shock due to contact with live parts or conductive work surfaces. They also provide protection against electrostatic discharge when used on surfaces with static electricity.

The S3 standard requires that safety shoes must have a resistance of at least 1 megohm when tested according to IEC 60384-1:2006+A1:2007 (or later versions). This means that if the wearer were to touch an energised conductor they would receive no more than 30 milliamperes of current flow through their body; this limits their exposure to an electric shock hazard.

S3 refers to safety shoes and boots that meet the requirements of EN ISO 20345:2015 (EN ISO 20345-1). These are high quality safety boots that provide a greater level of protection than those meeting EN ISO 20347:2012 (EN ISO 20345-2).

For safety shoes detail information read: https://www.anbusafety.com/what-are-safety-shoes/

What is the difference between S1 and S3 safety shoes?

S1 safety shoes are designed to provide protection from injuries from sharp objects. They are made from hard plastic and steel, and they have a steel toe cap. S1 safety shoes havenot a puncture-resistant sole that is also slip resistant. This type of shoe is ideal for industries such as construction and manufacturing.

S3 safety shoes are designed to provide protection against electrical hazards like static electricity, electrical shock and arc flash. They are made from rubber and plastic, but they still have steel toes that provide protection from injuries related to falling objects. S3 safety shoes are also slip resistant, which makes them ideal for manufacturing environments where there is a lot of moisture or oil present on the floor.

The best way to determine which type of shoe is right for your workplace is by understanding the hazards present in your environment and how those hazards could impact your feet if you don’t wear appropriate footwear like S1 or S3 safety shoes!

What is the difference between S2 and S3 safety shoes?

The S2 and S3 safety shoes are both EN ISO 20345 certified. They are also both manufactured in accordance with the European standard for footwear, EN ISO 20347.

The S2 safety shoe is a light-weight protective footwear that has been designed to be used in environments where only a limited amount of protection is necessary. The main difference between the S2 and S3 is that they use different types of materials, both of which have been designed to meet the requirements of their respective environments.

The S3 safety shoe is a heavier duty protective footwear that has been designed to be used in environments where more protection is required. This can include environments where there may be more risk of chemicals or debris being present as well as environments where there may be a greater risk of electrical shock or extreme temperatures (such as high heat or cold).

What is the difference between S1P and S3 safety shoes?

S1P shoes are designed for use in extreme conditions, such as oil and gas refineries, welding shops or chemical manufacturing plants. The sole is made of a special material that doesn’t conduct electricity. This is important because it prevents the wearer from being shocked by static electricity build-up when they walk on metal surfaces. for S1P safety shoes with steel toe cap and steel midsole and have anti static function.

S3 shoes can be worn anywhere that traditional steel-toe work boots are required. They have a steel toe cap and meet CE EN 20345 standards for impact protection. for S3 safety shoes have all the S1P safety shoes function, what;s more, the difference of S1P and S3 safety shoes are water proof function. for S3 safety shoes have waterproof function.

How to choose the right standard safety footwear?

When you are choosing the right standard safety footwear, there are some things that you need to consider. If you want to make sure that you pick out the right pair of shoes, then read on.

The first thing that you will want to do is make sure that they fit properly. You should never wear a pair of shoes that do not fit properly because they can cause blisters and other problems. If they are too tight, they may also cut off circulation in your feet and cause swelling or numbness in your toes.

When choosing a pair of shoes, make sure that they have good arch support and plenty of room for your toes to move around without being cramped together like sardines in a can. These types of shoes are much better at protecting your feet from injuries than ones without these features.

Another thing that you need to look for when buying safety shoes is sturdy construction. You want them to be able to withstand years of abuse from various hazards such as falling objects or chemicals spills without breaking down too soon or losing their protective properties altogether.

You should also make sure that the shoe has a slip resistant bottom so that it will not slide around on slippery surfaces when you are walking in them or even running if necessary.

Additional Resources

- What are safety shoes?

- What is steel toe cap?

- What is composite toe?

- Composite toe vs Steel toe vs Alloy toe

- Steel toe vs Aluminum toe vs Carbon toe

- CE EN20345: Safety shoes standard

- What is the function of safety shoes?

- Top brands of safety shoes

- Safety shoes size chart

- Best safety shoes for construction

Conclusion

It is best to have an S1, S2 and S3 safety shoes in your work environment so that you can be protected from the possible injuries. If you are just going to protect yourself from slipping on a wet surface, then get the S1 safety shoes. In case where you might get hit by heavy objects, use palm grip safety shoes because they’ll reduce shock and help reduce injuries when heavy objects fall on your feet. Use caustic chemical proof safety shoes if you are going to use a strong chemicals in your place of work.